PRESS-IT 2.0 - Ford Edition, basic-kit

Punch perfect holes into bumpers - without big effort.

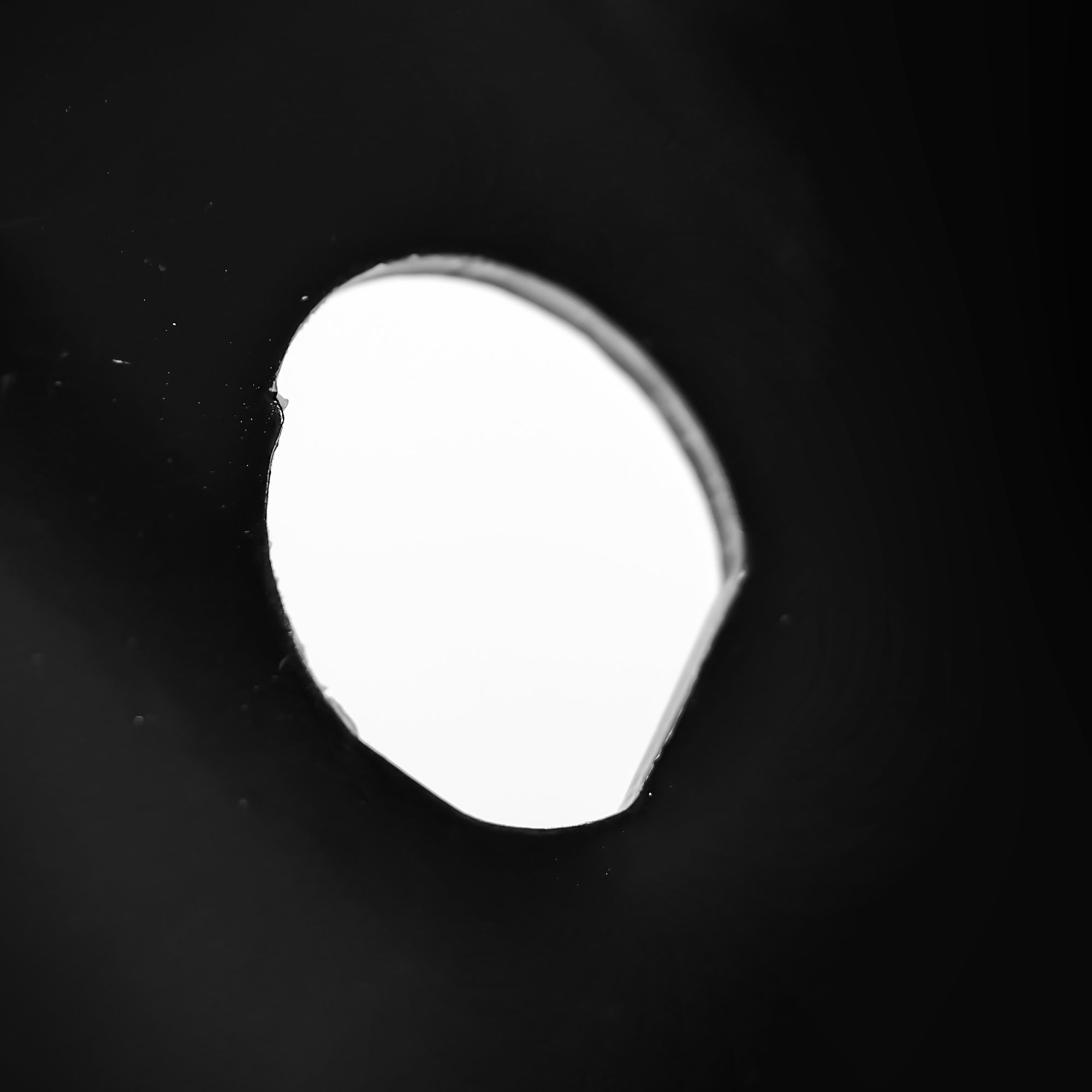

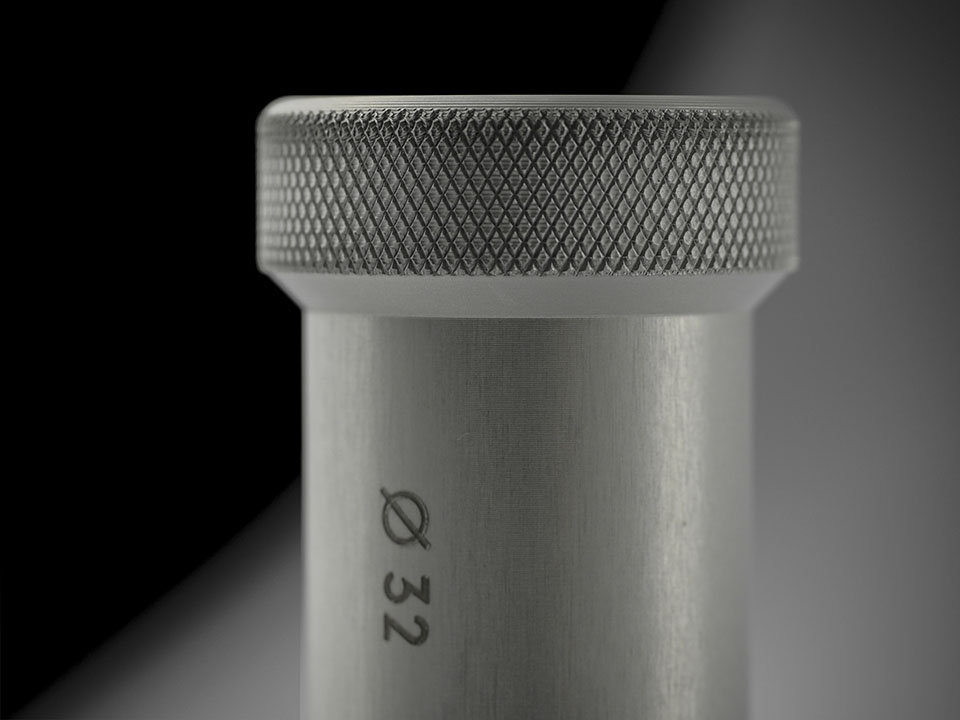

With the PRESS-IT 2.0, holes for PDCs (park distance controlers) can be easily, quickly and precisely punched into bumpers. The holes are punched after painting, because the paint is pulled into the hole and thus, it will not be damaged. The result are clean and smooth edges that do not interrupt the sensitive parking sensors. With our new Ford punches for the PRESS-IT 2.0, the holes for the parking sensors can be punched into the bumper in no time. The contour matrices are ”threaded” through the previously drilled hole and aligned with the given contour line. The precise cutting edge precisely punches the hole into the already painted bumper. Thus, time-consuming regrinding is avoided and saves time.

BENEFITS

-

Easy and professional punching of holes, according to the requirements of most automobile manufacturer

-

With the right cutter a custom-fit hole is punched into the bumper

SCOPE OF DELIVERY

-

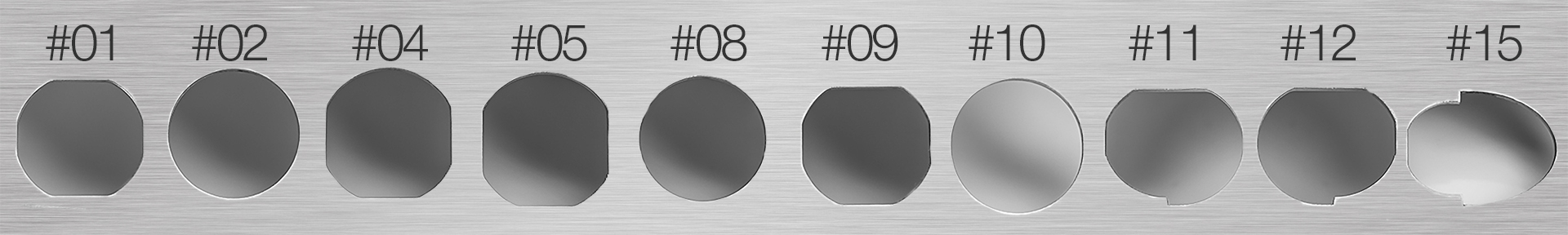

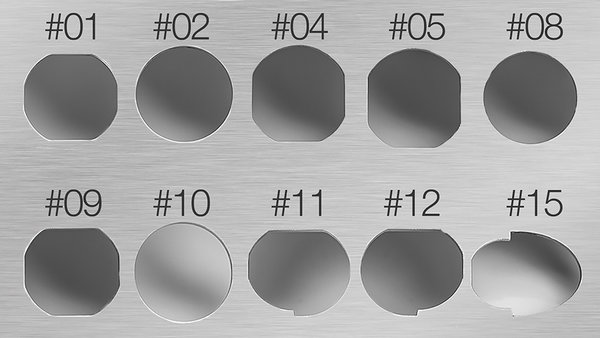

Punch #01

-

Punch #02

-

Punch #04

-

Punch #05

-

Punch #08

-

Punch #09

-

Punch #10

-

Punch #11

-

Punch #12

-

Punch #15

-

Drill 18 mm

-

Instruction manual

-

Case incl. Inlay

TECHNICAL DATA

| Material: | hardened tool steel, brunished |

| Made in: | Germany |

| Application by: | Ford |

Downloads for PRESS-IT 2.0 - Ford Edition, basic-kit

Accessories and spare-parts More products for PRESS-IT 2.0 - Ford Edition, basic-kit

These products could be interesting for you