PLASTOFUSED 2.0 Eco Version

Higher margin instead of expensive replacement.

Our new quick and easy solution for plastic-repair.

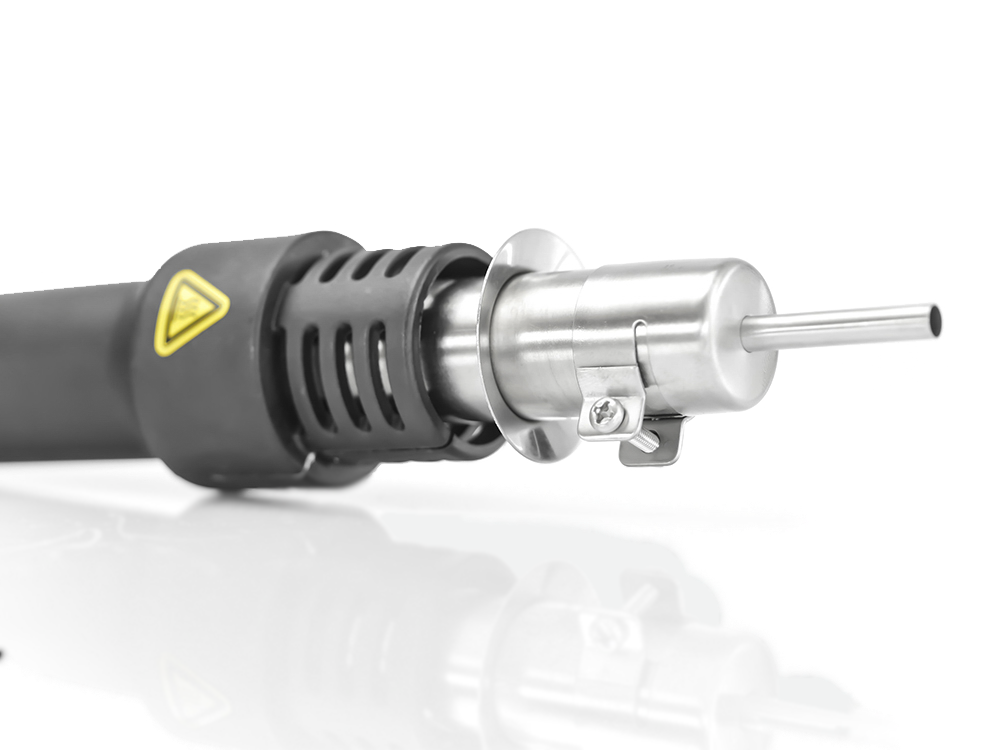

Our new PLASTOFUSED 2.0 is equipped with a LCD-display which shows the set temperature and the real temperature. We can reach higher temperatures by using a lower air volume as this is the key to be able to achive a good bonding. With this we get the plastic faster up to its own melding flow index (MFI) which then makes it ideal for bonding. With the special designed flat welding strip we created a tool for a quick, simple and high quality plastic-repair.

BENEFITS

-

Quick & efficiently

-

Ideal mixture of air pressure and temperature

-

Easy to handle

-

High-quality main-housing

-

Modern design

-

Wide range of accessories

-

Different Melting-Strips

-

Different fields of application

![]()

SCOPE OF DELIVERY

-

PLASTOFUSED 2.0 unit

-

Hose package 2m incl. handle

-

Hot air nozzle

-

Melting-Strips (PU 15 pcs.), black for Polypropylen (PP-EPDM)

-

Melting-Strips (PU 15 pcs.), black for Acrylnitril-Butadien-Styrol (ABS)

-

Robust cardboard packaging incl. inlay

-

Manual

TECHNICAL DATA

| Operating voltage: | 230 V~ / 50 Hz |

| Power: | 320 W / 1,49 A |

| Adjustable temperature: | 160…480 °C / 320…896 °F |

| Display: | double-spaced LCD-display |

| Nozzle ø: | 5 mm |

| Lenght of hose: | 1000 mm |

| Made in : | Germany |

Downloads for PLASTOFUSED 2.0 Eco Version

Accessories and spare-parts More products for PLASTOFUSED 2.0 Eco Version

These products could be interesting for you